A step forward: The new bulbous bow arrives

As we make progress on our journey to zero emissions, efficiency meets environmental responsibility. We are happy to share that one of our vessels, Aniara, has just been upgraded with a new bulbous bow.

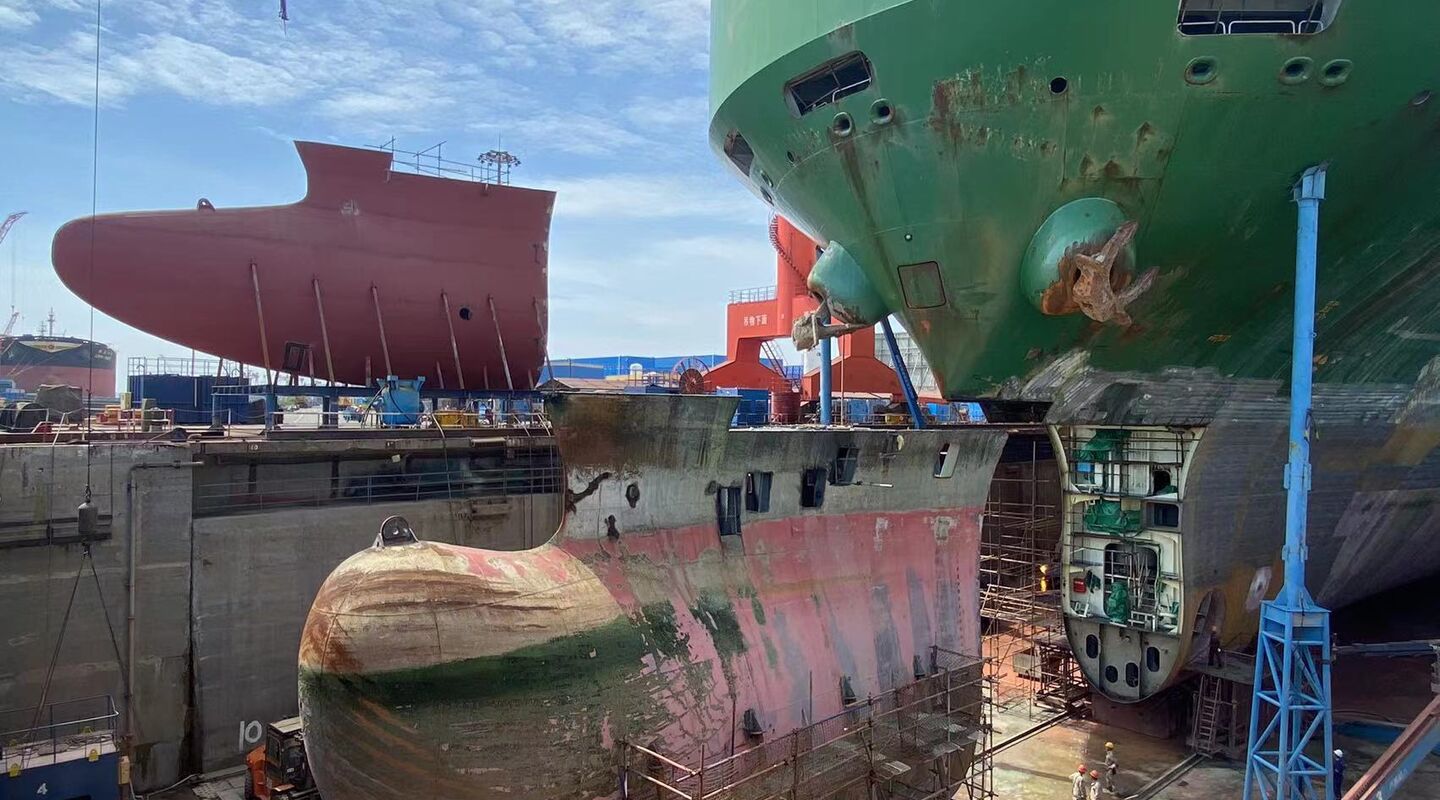

Installed meticulously at the renowned IMC-Yongyue (IMC-YY) repair yard in Zhoushan, China, the process was executed within the anticipated three-week dry-docking span.

And the news gets better - this bow upgrade is only the first; our vessels Oberon, Tijuca, and Tirranna await similar enhancements, with pre-fabrication efforts well underway.

Why the change?

A simple observation served as the basis for this effective change.

“The existing bulbous bow design was initially optimized for one very specific draught and speed. However, operational data clearly show that the vessels operate at lower draughts and speeds a significant portion of the time, where the existing design is not performing well, creating additional resistance to move through the water,” says Adam Larsson, Senior Manager of Energy Efficiency and Performance.

Teaming up with leading design partners, DSEC & DSME/Hanwha, the team carved out an optimized design that reduces resistance and promises considerable fuel savings.

To be precise, these fuel savings amount to an impressive average of 6%, translating to a reduction of 1,400 tonnes of CO2 annually for a single vessel.“We can expect even larger average savings if actual operating speeds are reduced in the future because the new design compared to the old will perform much better at lower speeds. Worth noticing is that at some operating conditions, such as lower draught about 8 m and 14 knots speed, the savings can be as much as up to 30%,” says Larsson.

A marvel in engineering

Designed with precision, the newly developed 137-tonne, 23-meter bulbous bow section underwent a two-month pre-fabrication phase, when it was coated and lifted into the dry dock using a large floating crane before installation. The yard carefully planned the operation, and the accuracy and efficiency of their work during this very limited timeframe was impressive!

“The most exciting part of the project is during the lifting and installation of the new bulbous bow section as it can never be guaranteed that everything will go as planned. Luckily, the new section matched perfectly well with the existing hull, and the yard managed to finalize the installation in less than a week, which is impressive” says Lars Ekren, Senior Manager in Newbuilding & Projects.

The teams behind the scenes

Adam Larsson head of the Energy Efficiency & Performance team in Marine Operations Management (MOM), initiated the project based on a fleet screening, by checking suitable retrofit candidates and defining a representative operating profile for optimization, and then by working together with our design partners to develop and verify the performance of the new bulbous bow design, by using extensive usage of computational fluid dynamics (CFD) simulations and physical scale model tests performed in South Korea. The collaboration didn’t just stop with the design — Lars Ekren from the MOM Newbuilding & Projects team transitioned into project management seamlessly in January, ensuring all operations met the highest standards.

“The two next bulb installations will take place in October for Tijuca and Oberon and the prefabrication work is already completed. With our great support from Anders and the other vessel managers we expect these installations to be executed successfully, even though we will naturally be a bit nervous when the installation is to take place,” says Lars.

The project is now carried out with the help of our vessel managers, and Anders Carlsson, Technical Superintendent at Wallenius Marine, whose presence was instrumental at the yard, overseeing the installation. His expectations, just like ours, are high regarding the performance of the new bulbous bow.

What’s the road ahead?

If you're pondering whether this is a one-off project, think again!

Wallenius Wilhelmsen has previously ventured into bulbous bow conversion endeavors, and this won't be the last. Such upgrades, combined with other energy efficiency ventures, are crucial in our journey to net zero emissions.

Stay tuned, as we continue to sail into the future, pioneering change.