Breakbulk packing guide: What you need to know

Want advice on how to best prepare your packing, marking and securing points to ensure on-time, cost-efficient and safe RoRo shipping for your products? Read our useful guide.

Why are packing and securing points important?

While underdeck stowage on our vessels will protect your products from weather conditions, a vessel at sea is exposed to multiple motions, accelerations and temperature variations – and your preparations on packing, marking and securing points are important to withstand these forces.

What happens to a vessel at sea?

Vessels are affected by six different motions that can occur simultaneously and which combine into three types of acceleration – vertical, transversal and longitudinal. We follow IMO regulations to ensure that cargo is firmly secured to withstand these forces.

What are my responsibilities when it comes to packing?

Packing is governed by IMO/CSS regulations and the carrier and shipper must both play their respective parts to ensure safe and secure transportation.

While it's the responsibility of carriers to handle products with care, and stow, secure and deliver them to their destination safely, shippers must prepare their products for transport to ensure they are fit for the intended sea voyage and type of vessel.

What do I need to know about packing and securing points?

The first thing to understand is that packing your products shouldn't be a hassle, if you know what constitutes good packing.

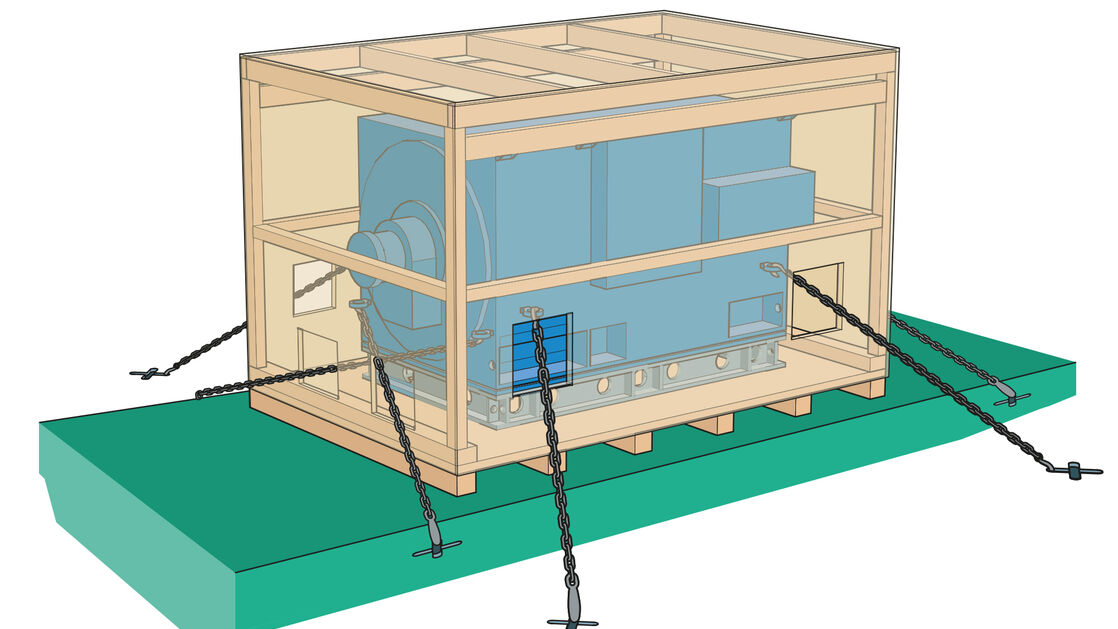

Secondly, methods of packing vary for products with direct lashing points and for products without direct lashing points. Securing points are critical for lashing your cargo onboard the vessel and must be attached directly to the cargo inside the packing or from the packing if the cargo and packing can be considered one solid unit.

For products above 10MT with direct lashing points:

- Secure directly as required by IMO and not by top over lashing.

- The total maximum securing load of the lashing points must correspond to the own weight of the cargo.

- The position of lashing points must be suitable to secure the cargo in all directions.

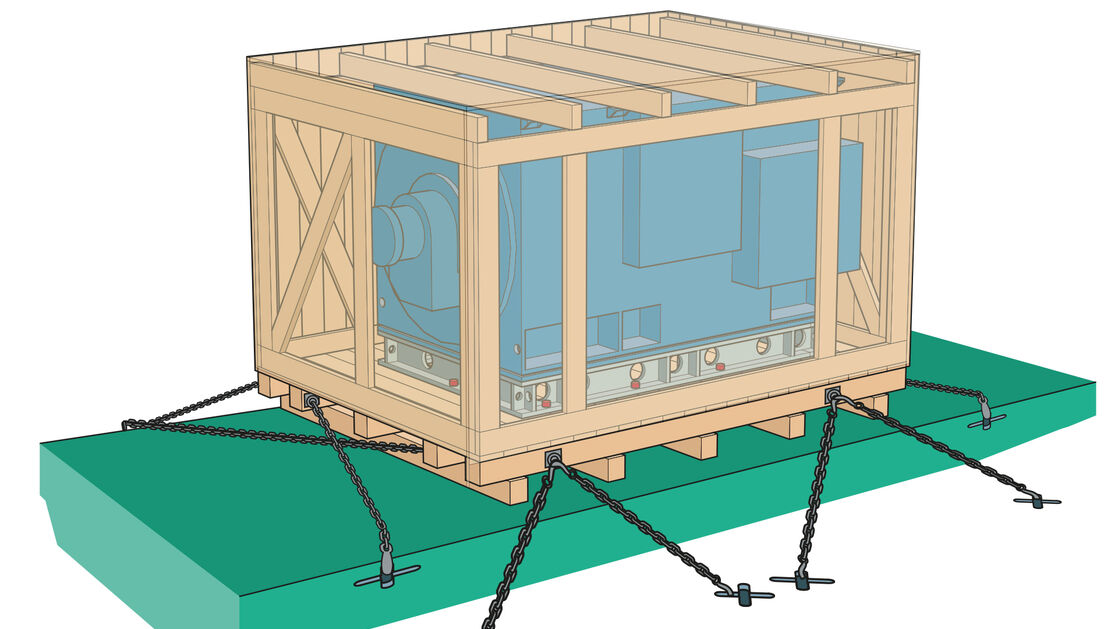

For products above 10MT without direct lashing points:

- Drawings and pictorial descriptions of the cargo must be displayed outside of the packing and/or sent via email.

- Clear documentation of securing arrangement inside the packing must be provided.

- Lashing points of sufficient strength and number must be fitted to the outside of the case and must be marked on the packing or advised.

- The total maximum securing load must correspond to own weight of the cargo on each side of the case.

- Codes and/or standards that the packing complies to must be provided

These are a few of the requirements you need to consider but are guidelines only. Talk to our customer service or your Wallenius Wilhelmsen account manager to find the best packing solution for your products.

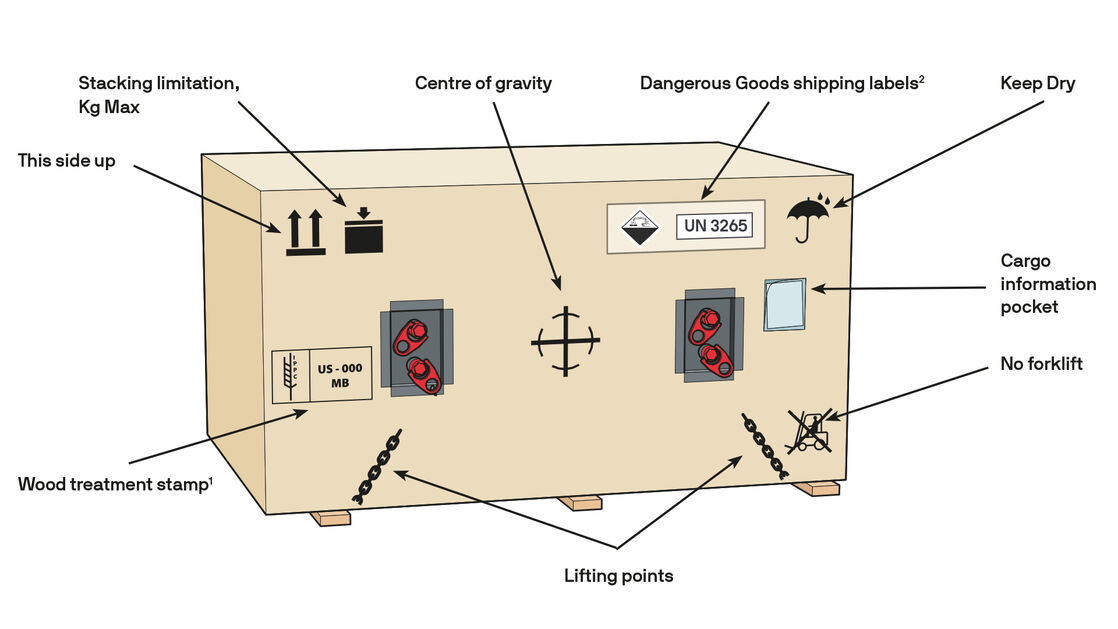

What labelling and marking needs to be on the unit?

Marking on packing provides important information to the carrier and stevedores handling your products and must comply with international standards.

The following information should be made available in a plastic pocket or stamped on the packing:

- Port of load and port of discharge

- Wood treatment

- Consignee

- Dimensions (length x width x height)

- Gross mass

- Position of centre of gravity

- Transport drawings/picture of cargo